VENEER DRYER UPGRADES

VENEER DRYER UPGRADES

Westmill specializes in dryer modification projects and has upgraded almost every style and brand of dryer existing today.

As dryers age, they begin to leak and use more energy to maintain the temperature set-point. Dryer production drops and maintenance costs rise. When the dryers can no longer keep up with production demands, owners often believe their only option is to purchase a new dryer.

Consider a Westmill “Better Than New” dryer upgrade, before making the costly decision to purchase new. Featuring quality Westmill components, your upgraded machine will look, operate, and perform like a new state-of-the-art dryer — at significant savings versus new. Rebuilding also saves considerable permitting costs and time, with faster delivery and reduced downtime compared to a new dryer.

Westmill Has Upgraded many Styles and Brands of Dryer

- COE M-72 Jet

- USNR M208 Jet

- Raute 4-deck Jet

- Moore Longitudinal

- Jacksonville Moore Jet

- EV Prentice Longitudinal

- Proctor Swartz Jet Screen

- COE M-62 Jet

- COE M-95 Jet

- Raute 6-deck Jet

- COE Longitudinal

- Moore Jet

- Babcock Screen

- Grenzebach

- Plymac

Westmill Dryer Technology Upgrade Components

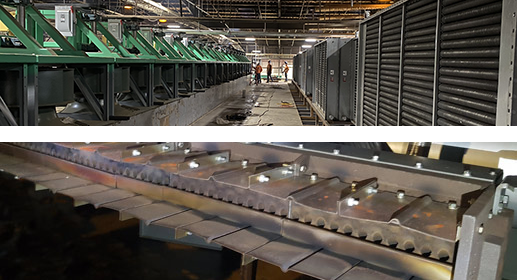

dryer floor & expansion rollers

Westmill dryer floors are manufactured with stainless steel (2-sided) insulated panels for maximum longevity. Our exclusively designed Expansion Rollers can withstand high static loading over a longer period. Made of high-strength steel and built to move.

seal-welded upper housing

Westmill’s “Minimal Heat Transfer” insulated upper housing system is designed to reduce energy costs by virtually eliminating metal-to-metal contact between the inner and outer walls of the dryer’s roof and siding.

roll assemblies & jet tubes

Westmill’s Dura-Cast™ Dryer Roll Conveyor System utilizes standard “off-the-shelf” components available from Westmill. Our company also manufactures our jet tubes using 16-gauge sheet metal. Westmill jet tubes ft. high-velocity orifices for max air flow and heat transfer.

dryer doors & door hardware

Robust and easy to use, our famous hardware keeps your Dryer sealed and workers safe from unnecessary strain. Westmill doors are available in all sizes for any dryer. Our doors can be designed to fit your existing OEM hardware and can be quickly changed out.

dryer heating equipment

Natural gas, steam coils, thermal oil coils and direct-fired hot air heating systems available. The Steam Coils that we supply are high-efficiency single-pass steam coils designed specifically for Westmill by Armstrong-Hunt. Our standard gas burners are Low NOx Maxon Crossfire Burners designed for maximized performance while minimizing emissions.

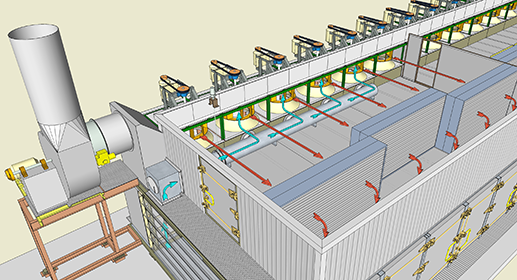

hot-air circulation fans

In an ongoing effort to reduce installation costs AND minimize downtime, Westmill provides pre-assembled modular components in many areas, including fans modules, door-frame-hardware modules, burner assemblies, and gas trains.

chain tensioner & drive tower

Westmill’s Veneer Pneumatic Chain Tensioner keeps the dryer chain tight and prevents binding. Maximize veneer recovery and reduce maintenance and downtime with our Dryer Drive Tower. Featuring an independent motor and Variable Frequency Drive for each deck.

water misting system

A highly effective method has been developed for minimizing dryer fires caused by fuel buildup on the dryer floor. The system provides a metered water spray within the dryer to increase the interior dryer humidity level and raise the ‘flash point’ significantly. Resulting in a significant reduction of dryer fires.

quick-change dryer baffle

Removing and replacing roll baffles now takes under 1-hour vs. 16-man-hours of very labor-intensive work to change out a baffle set. A unique feature of this innovation is that you are not required to remove the existing rolls, chain, sprockets, star gears, or jet tubes to replace the Roll Baffles.

dryer humidity control

Providing an effective method of controlling end-wall dryer emissions, to increase production, save energy, improve veneer quality, and reduce the risk of dryer fires. Our 2PEx technology Provides unparalleled control of humidity along the entire dryer’s length, resulting in increased production, energy savings, and greatly improved veneer quality.

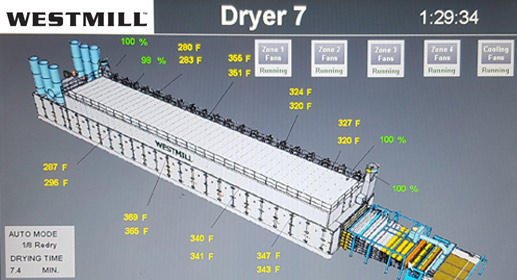

programing & controls

Westmill’s Dryer Control System functionality, ease of use, and reliability are so highly regarded that we have customers who have standardized this system across operations in multiple locations – even for dryers not built by Westmill.

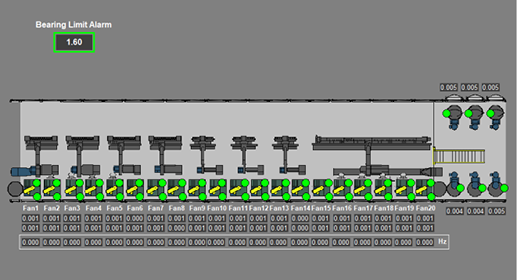

bearing vibration monitoring

Westmill has identified and pioneered an easy-to-incorporate solution that significantly and effortlessly enhances a plant’s preventative maintenance regime while increasing a dryer’s uptime.