About Westmill Industries

COMPANY OVERVIEW

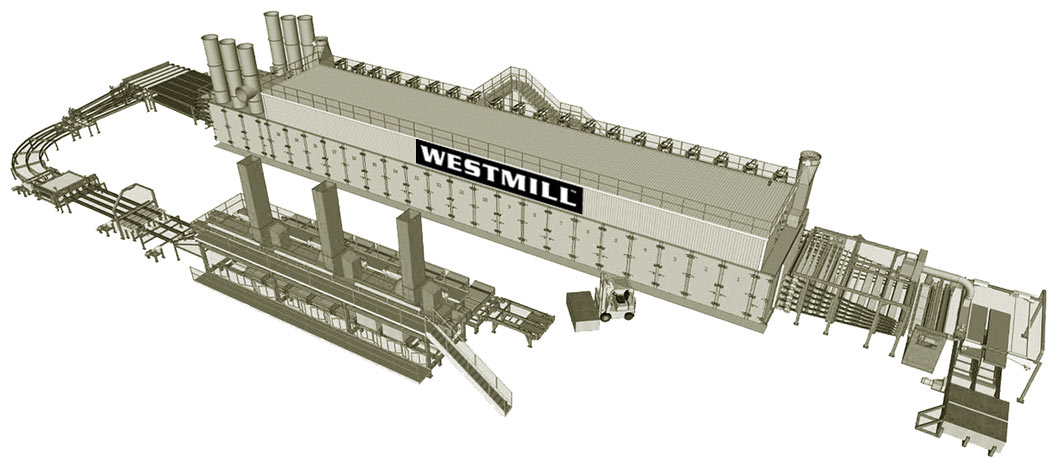

Established in 1975, Westmill is a second-generation family business with a strong team of knowledgeable employees. With three locations in North America, WESTMILL specializes in the design and manufacturer of new dryers, panel board dryer technology upgrades, as well as parts and accessories.

CORE VALUES

Westmill’s core values are embedded in the company’s culture and are the foundation of our success:

- The customer always comes first

- Pride in our work

- Honesty, integrity, and humility

- Flexible and innovative with a can-do attitude

- Teamwork

HALF-CENTURY HISTORY, REPUTATION AND BRAND

Westmill is well known and respected for its long history and brand. The Company was awarded the prestigious 2010 Innovator of the Year Award and 2013 Supplier of the Year Award in the Materials/Supplies category for the Engineered Wood Technology Association (EWTA).

The Company is a member of EWTA, FP Innovations, and the Decorative Hardwoods Association (formerly HPVA).

Infeed Chain Conveyor

A typical veneer dryer feeds from 3 veneer stacks simultaneously. The proposed WESTMILL® Dryer Infeed Chain Conveyor will allow Atco Wood Products to feed 3 stacks, and to store 3 stacks in waiting, ready to load as required. A forklift operator can load the storage chains while the dryer is being fed.

The WESTMILL® Infeed Chain Conveyor senses veneer loads as they are placed by the forklift, and automatically indexes the load position to match the vacuum feeder head spacing. This helps reduce plug ups while feeding the dryer and helps prevent sheet overlap along 8’ edges and corners. Of course, manual control is also supplied.

The WESTMILL® Infeed Chain Conveyor supply includes:

- Strong forklift-proof welded steel framework, complete with safety load stops at forklift end and at scissor lift end

- Heavy duty load backstop to assist load positioning by forklift

- Three runs of 81X chain with reversible 81X S-drive complete with individual screw-type chain take-ups per chain

- Return chains are housed inside strong 8” x 4” steel tube frame for safety

- Steel 12 tooth drive sprockets on 2-3/16” diameter C1045 drive shaft

- Motor with gear reducer, mounted outboard of veneer line

- Strong RC100 duplex chain drive from motor to conveyor, complete with guard.

- All 81X idler sprockets feature re-greaseable pins to deliver grease to sprocket bore.

- All electrical devices pre-wired to a junction box

- All components are supplied standard in inch sizes for North American customers. Metric components available upon request.

- Automatic feed sequence per the following:

- Photo-eye to detect when load is deposited. Advances load to predetermined position

- Limit switches or photo eyes to set predetermined gaps between loads to match spacing on your vacuum feeder heads (or for manual feed) to help prevent plug ups while feeding the dryer, and prevent sheet overlap along 8’ edges and corners

Scissor Lifts (Hoist)

The WESTMILL® Dryer Infeed Heavy-Duty (HD) Scissor Lift is rugged and dependable and allows you to support up to 22,000 lbs. of veneer – sufficient capacity for (3) loads of the heaviest green Sap veneer of any species.

Scissor Lift Hoist Details:

- Collapsed Height 16.5”; 76” wide x 192” wide deck (Dimensions can be altered to suit your application)

- 22,000 LBS Capacity

- Minimum 3:1 structural factor of safety

- Gravity roll-case on top of lift:

- 3-1/2” diameter rollers x 11 gauge on 6” centers; 15” distance between frame rails

- Edge load support tubes 4” x 3” x 184-1/8” long

- All pins on the Giant X-Lift are fabricated from hardened steel. The arms on the Giant X-Lift are CNC machined.

- Lube for life bushings with a larger bearing surface area than found on a typical roller bearing, and greater capacity than a bronze bushing.

- Ram roller alignment and correct positioning of the hydraulic cylinder within the lifting arms will be maintained with flanges.

- EASY TO MAINTAIN: Replaceable wear-guides affixed to the lifting arms and wedge plates.

- Safety lock-out pin on each leg.

Accumulator

WESTMILL®’s Dryer Infeed Load Accumulator allows for uninterrupted feeding of the dryer during the replacement of the infeed loads. A load replacement can take 45 to 120 seconds depending on load quality and the efficiency of the operator.

With an accumulator, the veneer production through your dryer remains constant as gaps between the veneer sheets will affect dryer airflow and temperature levels, both of which influence the drying process.

The accumulator supports the veneer during a load change. The dryer infeed operator activates a hand-operated valve that signals all 4 pneumatic cylinders to retract. As the cylinders retract, the front and back accumulator rolls (each driven by a pair of cylinders) move in underneath and towards the middle of the remaining 2” of veneer being fed into the dryer (see picture at the top of the next page). The rolls move via a gear “rack-and-pinion” design.

Any veneer species may be used, as the design can accommodate different species weights (due to differing densities and moisture sorts – heartwood, sapwood).

WESTMILL® supply includes:

- Main frame

- Roll assemblies with spur gears, rack, and slider assemblies.

- Pneumatic cylinders and pneumatic lines to one main hook-up

- Filter/Regulator/Lubricator unit.

- Telescoping weld-on leg extensions for precise field elevation positioning (shipped loose)

Vacuum Feeder

The proposed WESTMILL® Powered Roll Vacuum Feeder is robust in design in order to maintain the highest possible feeding rates.

Vacuum is used to pick up the top sheet from the veneer loads. The sheets are automatically advanced forward to the feeder tipple stop gate.

Manually feeding veneer at the dryer infeed is a repetitive motion that can be virtually eliminated using a Vacuum Feeder, reducing repetitive strain injuries and ensuring your dryer remains full.

WESTMILL® supply includes:

- Main frame (mounted to tipple feeder)

- 25 HP vacuum fan assembly complete with motor, sheaves, and v-belts (generally mounted over top of infeed roll case).

- Mounting plate for fan, complete with vibration isolators for fan mounting.

- Three vacuum heads including up/down cylinders and pneumatic valves.

- One shut-off damper per head including one pneumatic trunion cylinder per damper

- All pneumatic cylinders, valves, and pneumatic lines to one main customer hook-up

- Rigid duct connector between vacuum feeder and fan assembly.

- Filter/Regulator/Lubricator unit at main air connection

- PVC exhaust header complete with mist separator. Keeps oil out of plant air to help improve air-quality inside the plant.

Electrically Actuated Infeed Feeder/Tipple

WESTMILL® developed a new Infeed Tipple that has eliminated hydraulic cylinders in favor of an electric linear actuator.

The innovations built into the new WESTMILL® tipple produce the following benefits for the customer:

- Increased energy efficiency – A nitrogen-filled accumulator serves to counterbalance and significantly reduce the mass of the tipple feeder head from over 3,900 lbs. to only 60 lbs. This has reduced the horsepower required of the electric actuator.

- Increased sheet feed rate – counterweight allows quicker reaction time on the actuator – can continuously maintain over 22 feeds per minute.

- Reduced wood breakage – adjustable back roll limits bending of the veneer sheet and reduces wood breakage.

- Increased accuracy – the single high-force electric linear actuator is balanced by a torque-arm and controlled by a servomotor which increases positioning accuracy in comparison to a hydraulic unit with two cylinders.

WESTMILL has kept many of the same components as found on the original Hydraulic Tipple, including the quickly interchangeable pinch wheel head assemblies with solid feeder wheels.

Deck Infeed Rollcase

Included in this proposal is a 6 Deck Infeed Rollcase Section. This infeed section includes a heavy-duty channel framework & side rails. It is supplied with rolls, gudgeons, roller chain sprockets, chain, infeed tray nosings (duck bills), overlappers, c/w pneumatics, guarding and all miscellaneous fasteners.

A separate drive for each deck is provided to speed-match to the Dryer. This provides a much smoother and more consistent dryer feed and overlap timing vs. a cross-over drive roll arrangement powered from the dryer’s main drive chain. A separate drive system also allows you to keep the main dryer chain-conveyor operating even when there is an infeed stoppage.

Hydraulic Power Unit (HPU)

The WESTMILL® standard Hydraulic Power Unit is sized to adequately power your Scissor Lift.

Some features include:

- Vickers or Bosch proportional valve for accurate Scissor Lift control

- Oil immersion heater

- All devices pre-wired to a junction box

- Accumulator

- ¾ HP Cooler Fans

- The Scissor Lift is supplied pre-plumbed and shop tested.

Westmill™ provides consulting, plant layout, and engineering services to ensure you get the right machine for your facility.