NEW DRYER INSTALLATIONS

NEW DRYER INSTALLATIONS

NEW DRYER INSTALLATIONS

NEW DRYER INSTALLATIONSYears of experience in building new dryers and rebuilding existing dryers has provided the essential basis to engineer, design and manufacture superior dryer systems.

Ever since our foundation in 1975, we have consistently maintained our core focus: to be the Leader in Board Drying Technologies. Our focus combined with our innovative culture has led to a continuous series of dryer improvements. Often, these same dryer improvements conceived, engineered, pioneered, and proven by Westmill, eventually end up being incorporated into competitors’ products.

Our success is based not only on technical excellence, but something else that our competition just could not, or would not provide: a willingness to tailor our solutions to meet the customers’ needs and budget.

Westmill’s new board dryers are the highest production, most energy-efficient dryers in the market today.

We have completed hundreds of projects and have established a large installation base of new and rebuilt board dryers throughout North America, South America, and Australasia.

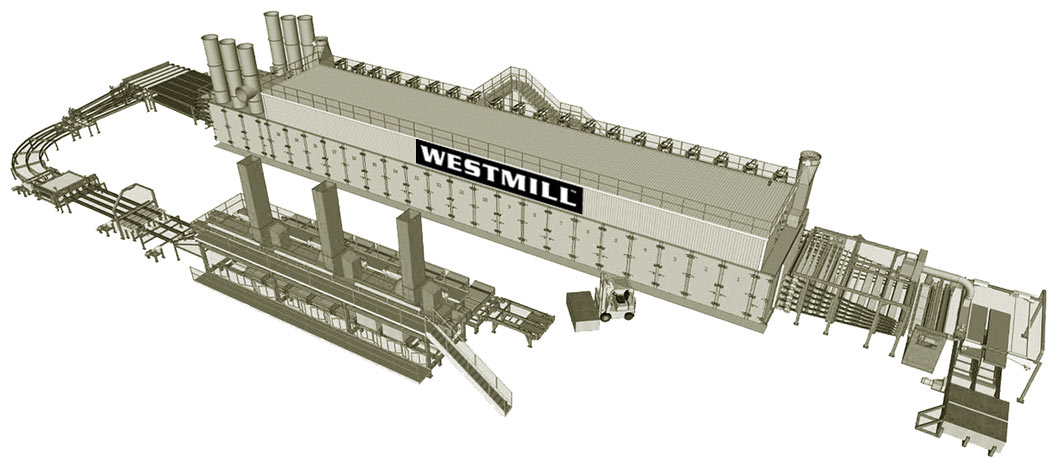

Westmill offers complete Veneer Drying Lines with an Automated Infeed, 4 or 6-Deck Jet-Dryers, Automated Outfeed, Grading, and Stacking Equipment.

Many features that are optional on other systems are standard equipment on Westmill’s Dryers. Our robust designs and quality components will provide you with many years of high production and minimum maintenance expenses.

Westmill offers complete Veneer Drying Lines with an Automated Infeed, 4 or 6-Deck Jet-Dryers, Automated Outfeed, Grading, and Stacking Equipment.

Many features that are optional on other systems are standard equipment on Westmill’s Dryers. Our robust designs and quality components will provide you with many years of high production and minimum maintenance expenses.