NEW VENEER DRYERS

NEW VENEER DRYERS

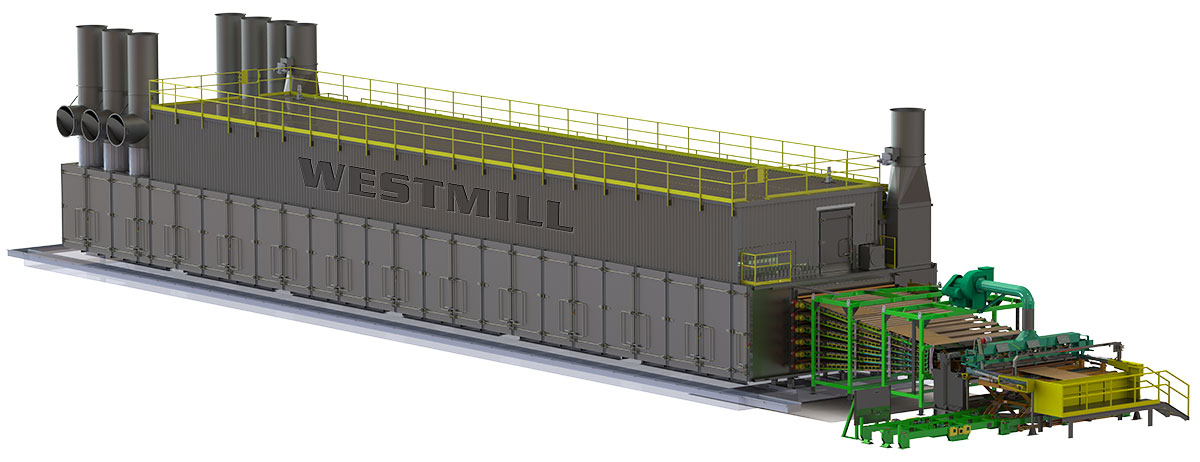

since 1975, veneer dryers have been the center of Westmill’s focus

Westmill has taken every step to make our Veneer Dryer the best available in the industry today. We have completed hundreds of projects and have established a large installation base of veneer dryers throughout the world. Within the plywood industry, we are ‘The Dryer Guys’.

By utilizing superior insulating techniques with a completely seal-welded housing, we have designed the most well-sealed and energy-efficient dryer in the market. Many features that are options on other dryers are standard equipment on a Westmill Dryer. Our robust designs, using quality components, will provide you with many years of consistent and high production with minimal maintenance expenses.

With an industry-best warranty, parts supply, maintenance consultations, and troubleshooting, Westmill will stand shoulder-to-shoulder with you. We’ve got your back.

VENEER DRYER COMPONENTS

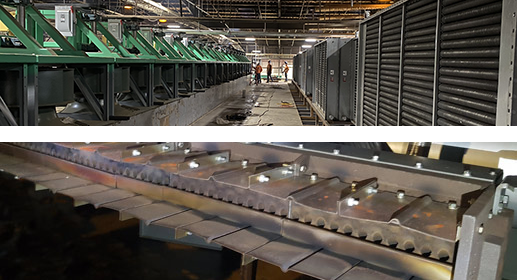

Dryer Floor & Expansion Rollers:

Westmill dryer floors are manufactured with stainless steel (2-sided) insulated panels for maximum longevity. Our exclusively designed Expansion Rollers can withstand high static loading over a longer period. Made of high-strength steel and built to move.

Upper Housing (Hotbox):

Westmill’s “Minimal Heat Transfer” insulated upper housing system is designed to reduce energy costs by virtually eliminating metal-to-metal contact between the inner and outer walls of the dryer’s roof and siding.

Roll Assemblies & Jet Tubes:

Westmill’s Dura-Cast™ Dryer Roll Conveyor System utilizes standard “off-the-shelf” components available from Westmill. Our company also manufactures our jet tubes using 16-gauge sheet metal. Westmill jet tubes ft. high-velocity orifices for max air flow and heat transfer.

Dryer Door & Door Hardware:

Robust and easy to use, our famous hardware keeps your Dryer sealed and workers safe from unnecessary strain. Westmill doors are available in all sizes for any dryer. Our doors can be designed to fit your existing OEM hardware and can be quickly changed out.

Dryer Heating Equipment:

Natural gas, steam coils, thermal oil coils and direct-fired hot air heating systems available. The Steam Coils that we supply are high-efficiency single-pass steam coils designed specifically for Westmill by Armstrong-Hunt. Our standard gas burners are Low NOx Maxon Crossfire Burners designed for maximized performance while minimizing emissions.

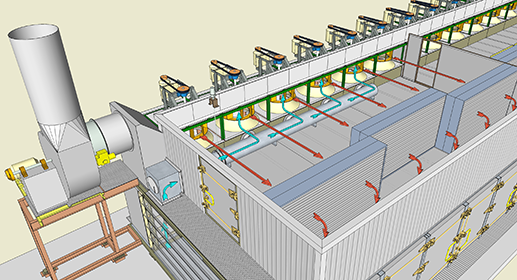

Hot-Air Circulation Fan:

Westmill fan modules are designed for quick and easy installation. To reduce installation time, each fan module comes pre-assembled complete with the fan, cone, bearings, sheaves, and spring packing gland.

Chain Tensioner & Drive Tower:

Westmill’s Veneer Pneumatic Chain Tensioner keeps the dryer chain tight and prevents binding. Maximize veneer recovery and reduce maintenance and downtime with our Dryer Drive Tower. Featuring an independent motor and Variable Frequency Drive for each deck.

Water Misting System:

A highly effective method has been developed for minimizing dryer fires caused by fuel buildup on the dryer floor. The system provides a metered water spray within the dryer to increase the interior dryer humidity level and raise the ‘flash point’ significantly. Resulting in a significant reduction of dryer fires.

Quick-Change Dryer Baffle System:

Removing and replacing roll baffles now takes under 1-hour vs. 16-man-hours of very labor-intensive work to change out a baffle set. A unique feature of this innovation is that you are not required to remove the existing rolls, chain, sprockets, star gears, or jet tubes to replace the Roll Baffles.

Cooling Section:

The cooling sections of Westmill dryers are configured with both intake and exhaust vane axial fans. We have configured the first cooler intake stack to allow plant air to be used for cooling during extremely hot summer months.

Dryer Humidity Control (WestVac & 2PEx):

Provides an effective method of controlling end-wall dryer emissions, to increase production, save energy, improve veneer quality, and reduce the risk of dryer fires. Our 2PEx technology Provides unparalleled control of humidity along the entire dryer’s length, resulting in increased production, energy savings, and greatly improved veneer quality.

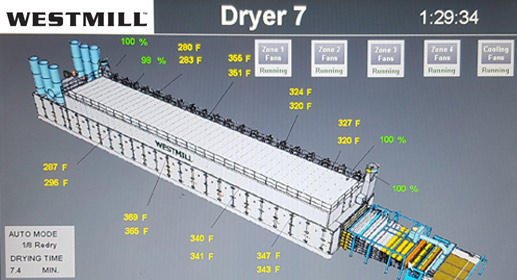

Programming & Controls:

Westmill’s Dryer Control System functionality, ease of use, and reliability are so highly regarded that we have customers who have standardized this system across operations in multiple locations – even for dryers not built by Westmill.

MORE FEATURES

- Zone partition walls with access doors in the upper duct.

- Adjustable air balancing plates to allow equal airflow to each deck.

- Roll baffles between each dryer section.

- Pre-assembled fan modules combine accurate shop alignment with quick field installation.

- Stack sections provided for the outside of the plant roof.

- Heating systems: natural gas and propane burners, steam coils, thermal oil coils, and direct-fired hot air heating systems are available.

Westmill provides consulting, plant layout, and engineering services to ensure you get the right machine for your facility.

NEW VENEER DRYERS

NEW VENEER DRYERS