Veneer Stacker & Outfeed

Veneer Stacker & Outfeed

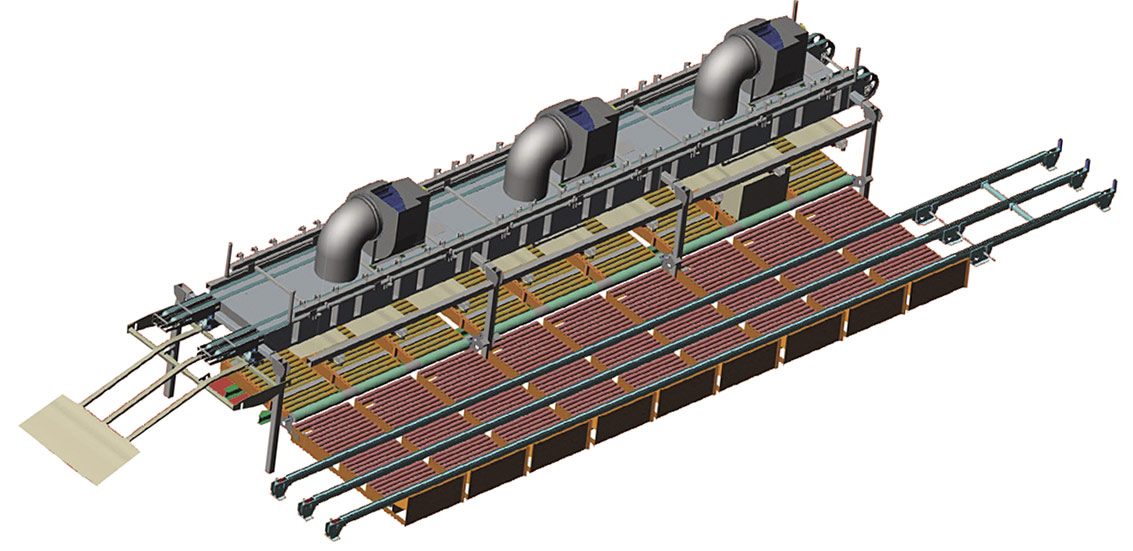

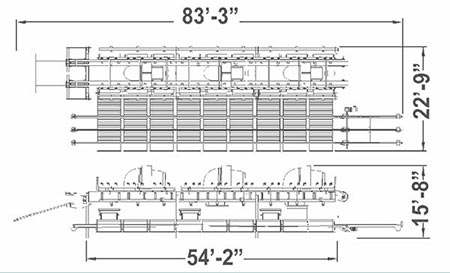

Westmill’s Stacker is available in configurations to stack both green and dry

We offer Stackers for full sheets (nominal 4′ clip width x 8′ length), half sheets (27″ clip width x 8′ length) and randoms (random clip width x 8′ length).

Stackers for other sheet sizes are also available.

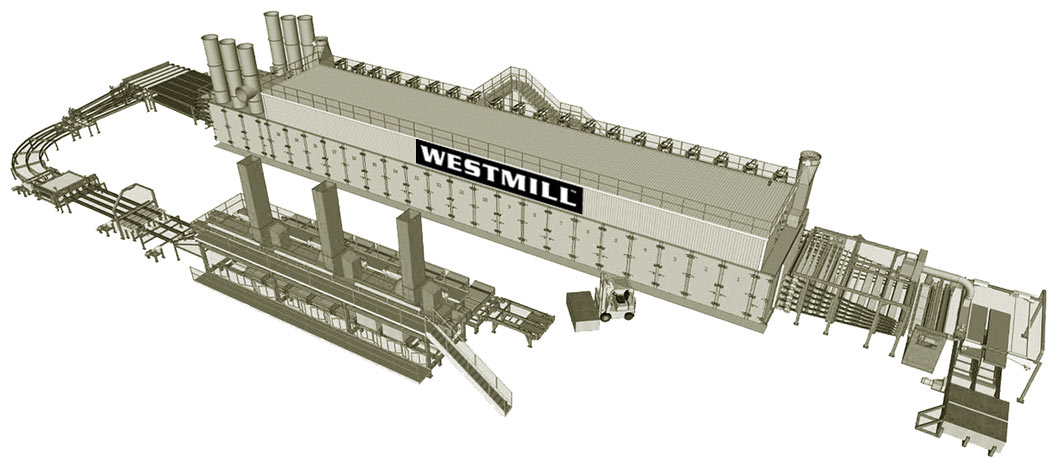

For some time, Westmill engineers have been working on re-designing around long-standing problems with existing Green and Dry Veneer Stacking Systems.

After months of re-design and engineering, Westmill has come up with a new design for cylinder, knock-off, vacuum chamber and transfer belt configuration that promises to deliver a better, more consistent stack quality. With our new system, we have incorporated design changes that allow cylinder replacement and maintenance while the machine is still in operation.

We have addressed problematic issues present in other Stackers that will improve your stack quality and stack handling.

Our new features include:

- Knock-off arms located between Vacuum Transport Belts

- Dome-shaped suction plates/vacuum chamber

- Tilting outfeed rollcase hoist-tops

Product Features

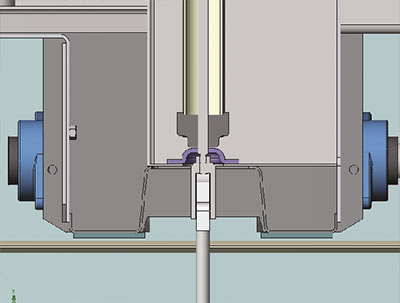

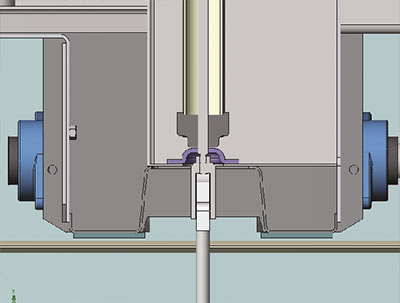

Knock-Off Arms Located between Vacuum Belts

Probably the most significant feature of the Westmill Stacker that differentiates ours from all other stackers in the industry today is how the knock-off arms are located between the two transport belts.

By knocking off sheets from between the two transport belts (and from the center of the vacuum chamber itself) we minimize concave and convex bending of the veneer sheet during knock-down, as seen with others’ stackers.

This gives us a clean and repeatable separation from the vacuum box with less force being required to separate the veneer from the vacuum belts than on any other Stacker.

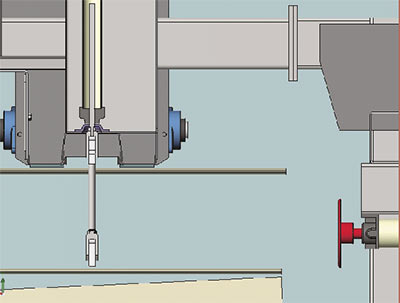

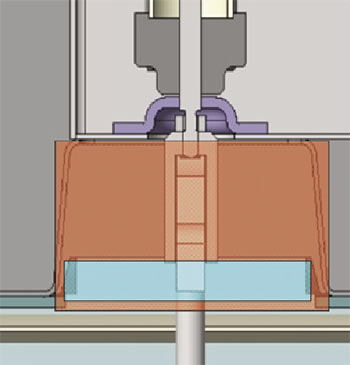

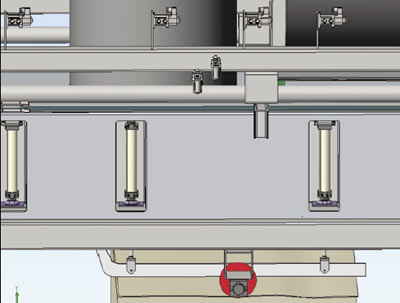

Knock-off cylinder extended

Advantages of our knock-down arm location

- Uniform release from vacuum

- Knock-off cylinder is inside sealed chamber separate from vacuum box; no suction is lost.

- Higher knock-off accuracy and lower cylinder speeds, producing better stacks

- More uniform vacuum along entire Stacker length from larger vacuum chamber volume

Close-up view of knock-off cylinder retracted

Dome-Shaped Vacuum Chamber

Westmill has redesigned and introduces a “dome-shaped” vacuum chamber approximately 4 times larger in size than others. This change provides greater volume and increased airflow between the veneer sheet and the vacuum chamber yielding very uniform vacuum along the entire stacker’s length no matter the number of sheets in the system.

With other designs, fluctuations in airflow cause problems with stack consistency.

With Westmill’s design, this will have minimal effect on the veneer transport and

knock-off consistency as our larger vacuum chamber is less prone to air evacuation/starvation.

The illustration shows the volume of Westmill’s vacuum air chamber (in red) in comparison to the size of others’ (in blue). One can clearly see the difference between the volumes of the two vacuum chambers.

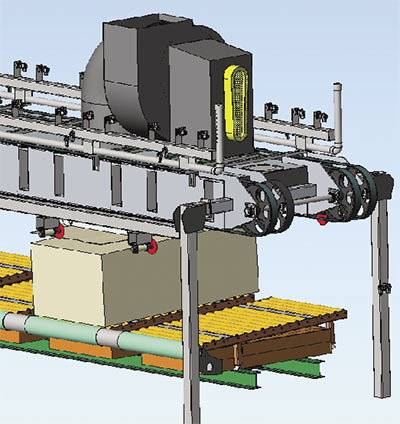

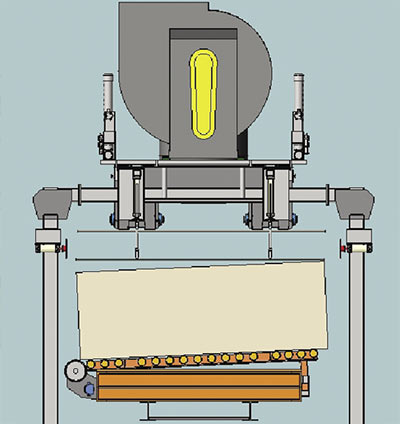

Tilting Outfeed Rollcase Hoist-Tops

A common problem found in many Stackers today is lack of positive driving force when clearing the stack out of a loaded bin. Typically, a powered roll transports the leading edge of a stack, and if slip occurs between the roll and the stack (which is level), the load will not move. This may require an operator to push the load. Deaths have occurred in the industry when a Stacker has not been locked out while doing this.

Westmill provides a rubber lagged roll, along with a tilting rollcase on top of the Scissor Lift.

During stacking, the Scissor Lift top is horizontally level, but when lowered, the hoist top tilts toward the outfeed direction, which provides more weighted force on the lagged powered outfeed pipe roll. This yields greater grip between the roll and the stack, which helps to ensure that the load will clear out of the Stacker.

Stack ready to unload via lagged pipe roll drive.

Scissor Lift in lowered position, tilted toward outfeed direction

Maintenance Access to Knock-off Cylinders

Because continuous operation and reliability are paramount in a veneer Stacker, the ability to shut down and safely work on a bin without having to shut down the entire machine is critical. We at Westmill are proud of our innovation which makes this possible.

With our new design, simply select the bin and de-activate at the controller, lock-out the cylinder air to that particular bin and place your knock-down arm ‘Safety Pins’ in place. You are now ready to remove and replace the knock-off cylinders in minutes by simply removing the clevis mounting pins.

We have also integrated a service catwalk that runs the entire length of the stacker and on both sides. From this catwalk, you are able to remove and replace knock-off cylinders while the machine is still in operation without disruption.

The dark gray region sees air under vacuum. The light gray cavity is not under vacuum, and is accessible from right.

Cylinders are accessed from outboard of the stacker, as the cylinders are mounted in a recess sealed cavity.

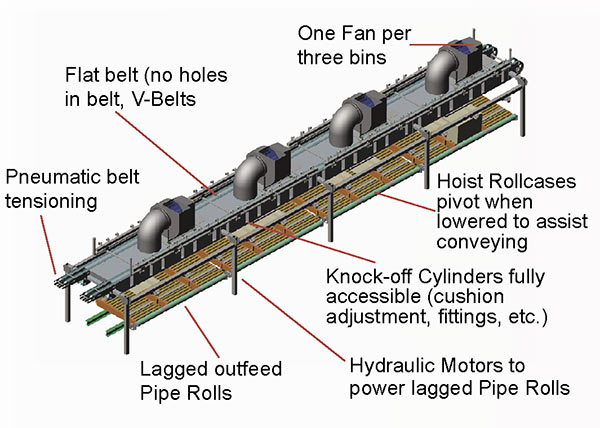

Standard Features included with all Stackers

- Knock-off arms, cylinders and sheet squaring pads for all bins

- Pneumatic belt tensioning, even on short Stackers.

- Flat belts (not holed belts nor v-belts)

- All cylinders and valves pre-plumbed, wired, and machine-shop tested

- One Vacuum fan with 25 HP motor per 3 bins

More Features

Dry Veneer Stacker Control System

Westmill’s Stacker Control system for Knock-off Control utilizes the Allen Bradley Controllogix L61 PLC Processor, mounted in an Operator’s Control Cabinet, and also incorporates a Panelview Plus 1500 Touch Screen operator interface. Other systems are available upon request (i.e.: Modicon Quantum Series, Omron, Mitsubishi).

Operator Console for Grade Station

- Stacker control power button, auto/manual buttons and grade buttons

15″ PanelView Touch Screen Station

- Start Stacker motors, assign grades to bins, alarming/diagnostics, Stacker set-up

- Bin Totals/Loads per shift reports

Stations for Stacker Bin Control

- One control station for every two bins. Hoist and bin unload, manual overrides

Stacker Outfeed Control Station

- Used to manually jog Stacker outfeed chains and to enable outfeed auto mode

Optional Fan Variable Frequency Drives (VFD’s)

Another unique feature of Westmill Dry Stacking system is that the Stacker’s vacuum pressure can be automatically adjusted and maintained by using VFDs on the Vacuum Fans.

- Multiple Pressure Transducers continuously monitor the manifold pressure in each section.

- Vacuum is maintained at the minimum required pressure, reducing knock-down arm speed and force required.

- Results in consistent stack quality and greatly reduced wear-and-tear on all knock-off related equipment.

- Ability to reduce fan speed or turn the fans off when a notification is received of a line stoppage from the Dryer Control System. Results in energy savings with the added bonus of greatly, reducing typical knock-down system maintenance.

Westmill provides consulting, plant layout, and engineering services to ensure you get the right machine for your facility.

Veneer Stacker & Outfeed

Veneer Stacker & Outfeed